Navigating the labyrinthine domain of Electric Vehicle (EV) technology entails a meticulous understanding of the intricate interplay between EV batteries, grounding systems, and the intricate realms of electrical engineering. This technical exposition delves deeper into the complexities of EV battery architectures, grounding intricacies, and their pivotal roles in shaping the future of electric mobility.

Delving into EV Battery Complexity: Technical Dynamics

Cell Chemistry and Voltage Considerations

EV battery intricacies encompass diverse chemistries, ranging from lithium-ion to solid-state configurations, each exhibiting distinctive voltage thresholds, specific energy densities, and charge-discharge kinetics. Grounding systems, calibrated to manage varying voltage potentials, ensure uniform energy distribution across cells, mitigating disparities and optimizing overall battery performance.

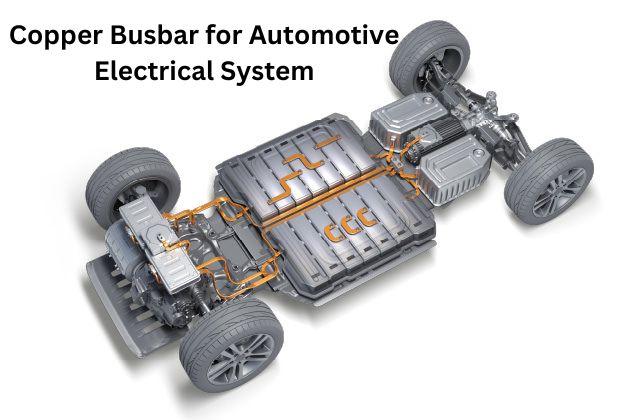

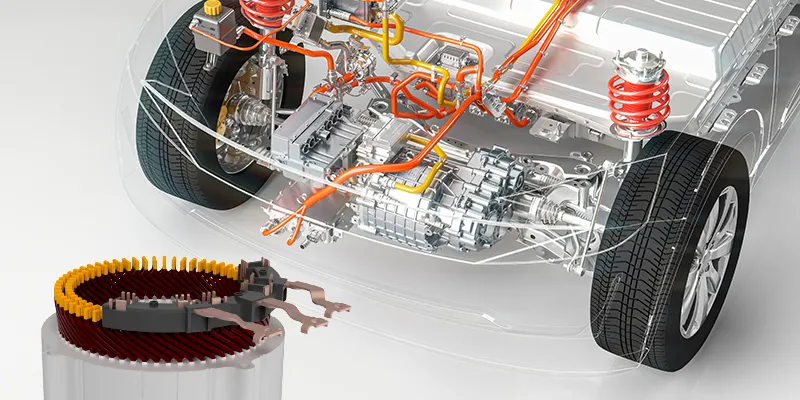

Powertrain Integration and System Optimization

EV powertrains, comprising battery packs, electric motors, and control electronics, demand precise coordination and optimization for seamless energy conversion. Grounding solutions within these powertrains play a pivotal role in managing electrical noise, ensuring efficient power transmission, and minimizing electromagnetic interference, enhancing overall system reliability and efficiency.

The Essence of Grounding in EV Safety and Efficiency

Mitigating Electrical Hazards and Leakage

Robust grounding systems within EV batteries act as guardians against electrical hazards, deflecting stray currents, voltage irregularities, and potential leakage. Their incorporation ensures a low-impedance pathway, diverting fault currents away from critical components, fortifying against catastrophic failures, and augmenting overall system safety.

Impedance Management and Resistance Minimization

Optimal grounding strategies focus on impedance management, emphasizing low-resistance pathways and minimized impedance loops. Precision-engineered grounding architectures, coupled with conductive materials and meticulous design considerations, mitigate resistive losses, enhancing energy efficiency and promoting longevity in EV battery systems.

Grounding’s Role in Advanced Battery Management

Electrostatic Discharge (ESD) Mitigation Strategies

Electrostatic Discharge (ESD) risks demand sophisticated grounding methodologies. Grounding solutions, fortified by conductive materials and controlled discharge mechanisms, dissipate accumulated electrostatic charges, averting potential cell damage, and preserving overall battery health in high-voltage EV systems.

Thermal Management and Heat Dissipation

EV batteries are prone to thermal fluctuations during charge-discharge cycles, necessitating robust thermal management solutions. Grounding systems, strategically integrated with thermal interfaces and conductive materials, facilitate efficient heat dissipation, mitigating thermal runaway risks, and maintaining optimal operating temperatures within battery packs.

Advancements Driving Future EV Grounding Solutions

Innovations in Material Science and Manufacturing

The evolution of EV battery technology hinges upon innovations in grounding solutions. Advancements in conductive materials, novel manufacturing techniques, and precision-engineered grounding architectures will pave the way for optimized grounding solutions, fostering enhanced safety and efficiency in next-generation electric vehicles.

Smart Grounding Solutions and Adaptive BMS Integration

The convergence of intelligent Battery Management Systems (BMS) with advanced grounding solutions heralds a new frontier in EV technology. Smart grounding solutions, empowered by real-time monitoring and adaptive control algorithms, optimize grounding efficacy, ensuring dynamic responses to evolving operational conditions in high-voltage EV systems.

Conclusion: The Paradigm Shift in Electric Mobility

The symbiotic relationship between EV batteries, grounding systems, and electrical engineering principles heralds a transformative era in electric mobility. Their harmonious interplay not only ensures safety, reliability, and efficiency but also shapes the trajectory towards a sustainable future marked by groundbreaking advancements in electric vehicle technology.

Pioneering the Evolution of Electric Mobility

The intricacies of EV battery architectures, grounding mechanisms, and electrical engineering principles epitomize a frontier of technological prowess and innovation. As the landscape of electric mobility continues to evolve, the synergy between advanced grounding solutions and EV battery technology will redefine the boundaries of electric mobility, driving advancements towards unprecedented levels of efficiency and reliability.