Overview:

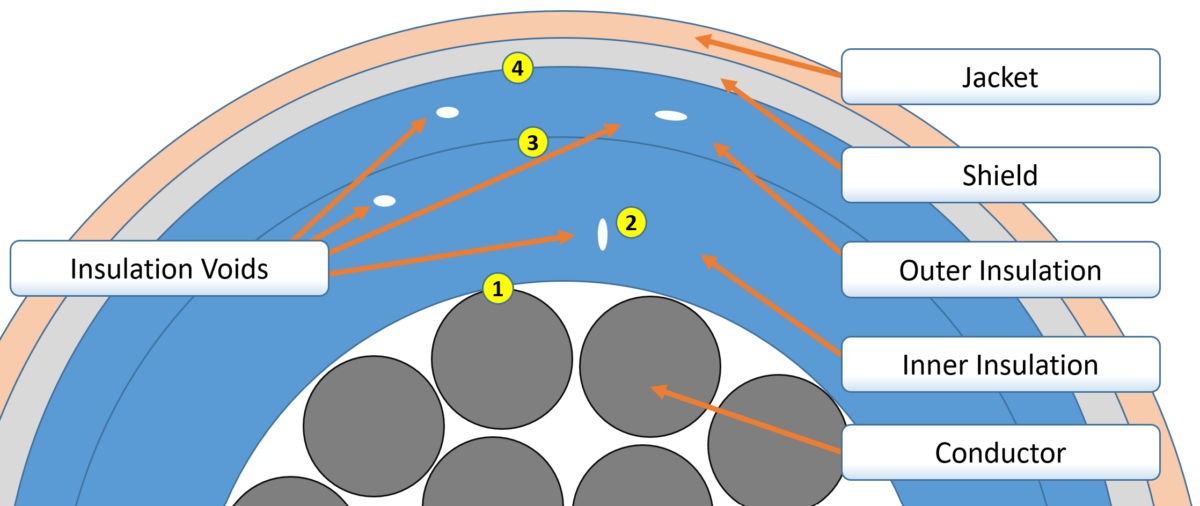

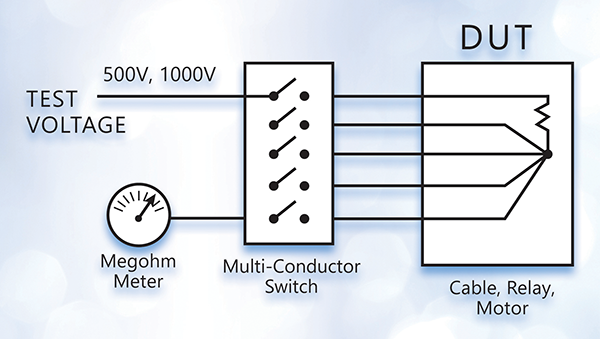

Partial Discharge (PD) testing is a diagnostic method used to evaluate the health of insulation systems in high-voltage equipment. This non-invasive test detects and measures partial discharges within insulation, helping identify potential weaknesses or defects that could lead to electrical breakdowns, equipment failures, or safety hazards. Continue reading “Partial Discharge Testing: Assessing Insulation Health in High-Voltage Systems”