Overview:

Hi-Pot (High Potential) testing, also known as Dielectric Withstand testing, is a crucial electrical safety test conducted to assess the integrity of insulation in electrical components and systems. This non-destructive test applies high voltage to verify insulation withstand capability, ensuring compliance with safety standards and preventing electrical breakdowns or leakage.

Hi-Pot Testing Process:

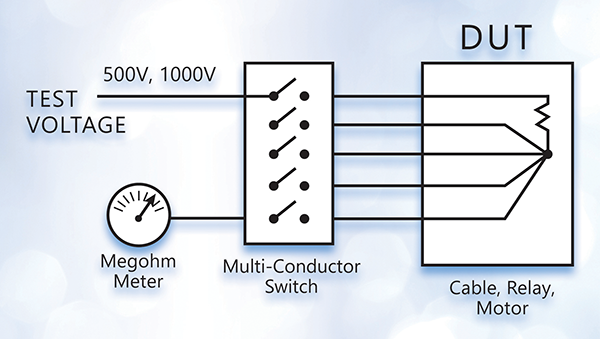

Test Setup and Equipment:

- Testing Apparatus: Utilizes specialized Hi-Pot test equipment capable of generating high voltages, typically higher than normal operating voltages.

- Test Specifications: Follows specific test standards and voltage levels defined by industry regulations or product requirements.

Test Execution:

- Voltage Application: Applies high voltage between conductors or between conductors and ground, stressing the insulation.

- Duration and Measurements: Maintains the applied voltage for a specified duration while monitoring for any current leakage or breakdown.

Pass/Fail Criteria:

- Acceptance Standards: Determines pass or fail based on set thresholds for current leakage or insulation breakdown.

- Safety Protocols: Implements safety measures to prevent damage to equipment and ensure personnel safety during testing procedures.

Importance and Applications:

Electrical Safety Assurance:

- Preventing Electrical Failures: Identifies potential weaknesses in insulation, preventing electrical shocks or equipment malfunctions.

- Compliance Standards: Ensures compliance with industry standards (e.g., UL, IEC, IEEE) and safety regulations.

Diverse Applications:

- Electronic Components: Validates insulation in cables, transformers, capacitors, and circuit boards.

- Power Systems: Tests insulation in high-voltage cables, switchgear, and power distribution systems.

Precision and Quality Assurance:

Test Calibration and Verification:

- Equipment Calibration: Ensures accuracy and reliability of Hi-Pot test equipment through periodic calibrations.

- Verification Checks: Conducts routine checks to verify proper functioning of testing apparatus before each test cycle.

Record-Keeping and Documentation:

- Test Records: Maintains detailed records of test parameters, results, and equipment used for compliance and traceability.

- Reporting: Generates test reports highlighting pass/fail results and any anomalies observed during testing.

Hi-Pot Testing plays a pivotal role in ensuring the safety and reliability of electrical components and systems. Its ability to identify potential insulation weaknesses and adherence to safety standards make it an indispensable process in electrical equipment manufacturing and maintenance.