Overview:

Infrared Testing, also known as Thermographic Inspection, is a non-destructive technique used to detect and analyze thermal patterns emitted by objects or systems. This method utilizes infrared cameras or thermal imaging equipment to visualize temperature variations, identifying anomalies or issues that might not be visible to the naked eye.

Infrared Testing Process:

Equipment Setup and Calibration:

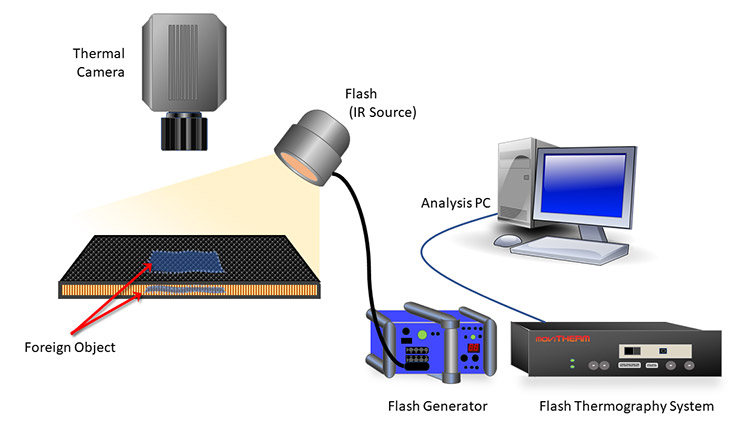

- Thermal Cameras: Utilizes specialized cameras capable of detecting and capturing infrared radiation emitted by objects.

- Calibration Checks: Regularly calibrates thermal imaging equipment for accurate temperature readings.

Test Execution:

- Scanning and Imaging: Captures infrared images of objects or systems under normal operating conditions.

- Temperature Analysis: Analyzes thermal patterns to identify temperature variations or anomalies.

Diagnostic Assessment:

- Anomaly Identification: Detects hotspots, cold spots, or irregular thermal patterns indicating potential issues or defects.

- Location of Thermal Abnormalities: Pinpoints areas for further inspection or maintenance based on temperature deviations.

Importance and Applications:

Condition Monitoring:

- Preventive Maintenance: Identifies potential faults or deteriorations in equipment before they result in failures.

- Predictive Analysis: Aids in predicting equipment malfunctions or failures based on temperature anomalies.

Diverse Applications:

- Electrical Systems: Detects loose connections, overloaded circuits, or faulty components in electrical panels or equipment.

- Mechanical Systems: Identifies bearing failures, insulation issues, or mechanical wear in machinery and rotating equipment.

- Building Inspections: Identifies insulation deficiencies, water ingress, or HVAC inefficiencies in building structures.

Precision and Quality Assurance:

Image Interpretation and Analysis:

- Thermal Image Review: Expert analysis interprets thermal images and identifies abnormal temperature patterns.

- Correlation with Equipment Condition: Links temperature variations to potential equipment faults or performance issues.

Reporting and Action Plans:

- Documentation: Documents findings with detailed thermal images, annotations, and identified anomalies.

- Recommendations: Provides recommendations for further inspections, repairs, or maintenance based on identified issues.

Infrared Testing serves as a valuable tool for detecting hidden issues or anomalies by visualizing temperature variations. Its ability to identify potential problems early helps in preventing failures and optimizing maintenance strategies in various industries.