Overview:

Resistance and Insulation Testing are fundamental electrical tests used to evaluate the electrical integrity of components, circuits, and insulation materials. These tests measure resistance levels and insulation resistance to assess the health and functionality of electrical systems, ensuring safety and reliability.

Resistance Testing Process:

Test Setup and Equipment:

- Ohmmeters or Multimeters: Utilizes precision measuring instruments to measure resistance levels in circuits or components.

- Test Conditions: Conducts tests under defined conditions, ensuring accurate measurements.

Test Execution:

- Measurement Connections: Connects test leads or probes to the circuit or component being tested.

- Resistance Measurement: Measures electrical resistance, determining the opposition to current flow in the system or component.

Diagnostic Assessment:

- Resistance Analysis: Analyzes resistance values against set thresholds or expected ranges for circuit or component functionality.

- Fault Identification: Identifies abnormalities or faults like open circuits, short circuits, or degraded connections based on resistance readings.

Insulation Testing Process:

Test Setup and Equipment:

- Insulation Testers (Megohmmeters): Employs high-voltage, low-current instruments to measure insulation resistance.

- Safety Precautions: Ensures safety measures, including grounding and appropriate equipment handling.

Test Execution:

- Insulation Measurement: Applies high voltage to assess the insulation resistance of cables, wires, or electrical systems.

- Insulation Resistance Calculation: Measures the leakage current and calculates insulation resistance values.

Diagnostic Assessment:

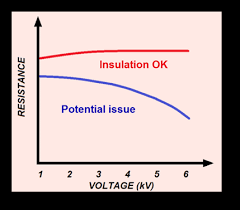

- Insulation Condition Evaluation: Assesses insulation health and integrity based on measured insulation resistance values.

- Insulation Deterioration Identification: Detects degradation, moisture ingress, or insulation breakdowns through low resistance readings.

Importance and Applications:

Electrical System Health Assessment:

- Preventive Maintenance: Helps identify potential faults or deteriorations before they escalate into failures.

- Compliance Verification: Ensures compliance with safety standards and regulations in electrical installations.

Diverse Applications:

- Industrial Machinery: Evaluates electrical integrity in motors, generators, and control systems.

- Building Wiring and Installations: Tests insulation integrity in wiring, cables, and electrical installations for safety and reliability.

Precision and Quality Assurance:

Calibration and Verification:

- Equipment Calibration: Regular calibration of testing instruments for accuracy and reliability.

- Validation Checks: Conducts routine checks to verify proper functioning of testing apparatus before each test cycle.

Data Analysis and Interpretation:

- Threshold Comparison: Compares measured resistance or insulation values with specified thresholds or standards.

- Fault Identification: Determines faults or potential issues based on resistance or insulation readings.

Resistance and Insulation Testing stand as essential procedures ensuring the safety, reliability, and functionality of electrical systems and components. Their ability to detect faults and assess insulation health aids in preventive maintenance and compliance verification in various industries.