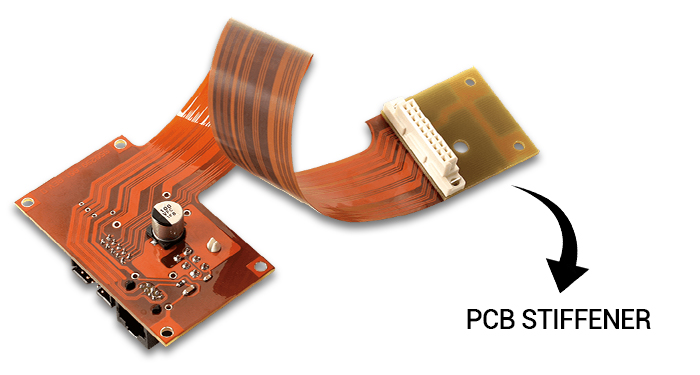

Circuit Board Stiffeners serve as crucial structural components in electronic systems, providing support, rigidity, and stability to printed circuit boards (PCBs). These stiffeners play a pivotal role in ensuring the mechanical integrity and reliability of PCB assemblies, especially in demanding environments.

Technical Specifications:

Construction and Material:

- Material Composition: Circuit Board Stiffeners are commonly fabricated from materials like FR-4 (fiberglass-reinforced epoxy laminate), aluminum, or other rigid materials.

- Design: Stiffeners are designed to reinforce and support the PCB, typically placed at edges or critical areas susceptible to mechanical stress.

Mechanical Properties:

- Rigidity: Stiffeners offer enhanced rigidity and support to prevent flexing or warping of PCBs, especially in applications subjected to vibrations or thermal cycles.

- Thickness and Dimensions: Vary based on PCB size and application requirements, typically ranging from 0.8mm to 3mm in thickness.

Manufacturing and Applications:

Manufacturing Processes:

- Stiffeners are manufactured through CNC machining, stamping, or molding processes to achieve precise dimensions and contours required for specific PCB designs.

- Adhesive or mechanical attachment methods are employed to secure stiffeners onto PCBs.

Applications:

- Industrial Electronics: Utilized in industrial control systems, machinery, and instrumentation to reinforce PCBs in rugged environments.

- Aerospace and Automotive: Applied in aerospace and automotive electronics where PCBs are subjected to high vibrations and temperature fluctuations.

- Consumer Electronics: Used in devices where thin and flexible PCBs require reinforcement and support.

Advantages and Considerations:

Advantages of Circuit Board Stiffeners:

- Enhanced Mechanical Support: Stiffeners provide structural reinforcement, preventing PCBs from flexing or bending, ensuring reliability.

- Improved Reliability: Minimize the risk of PCB failure due to mechanical stress or environmental factors.

Considerations:

- Design Compatibility: Stiffeners must be designed and selected to match PCB layouts and dimensions for effective support without interfering with components or connections.

- Thermal Considerations: Ensuring compatibility with thermal expansion coefficients of the PCB material to prevent mechanical stress during temperature variations.

Circuit Board Stiffeners play a critical role in reinforcing and stabilizing PCBs, ensuring their mechanical integrity and reliability in various electronic applications. Their structural support and reinforcement capabilities make them indispensable components in demanding electronic systems.