Standoff Insulators are essential components in electrical systems, providing insulation, support, and separation between conductive elements. These insulators serve a critical role in maintaining electrical integrity and preventing electrical faults or short circuits in various applications.

Technical Specifications:

Construction and Material:

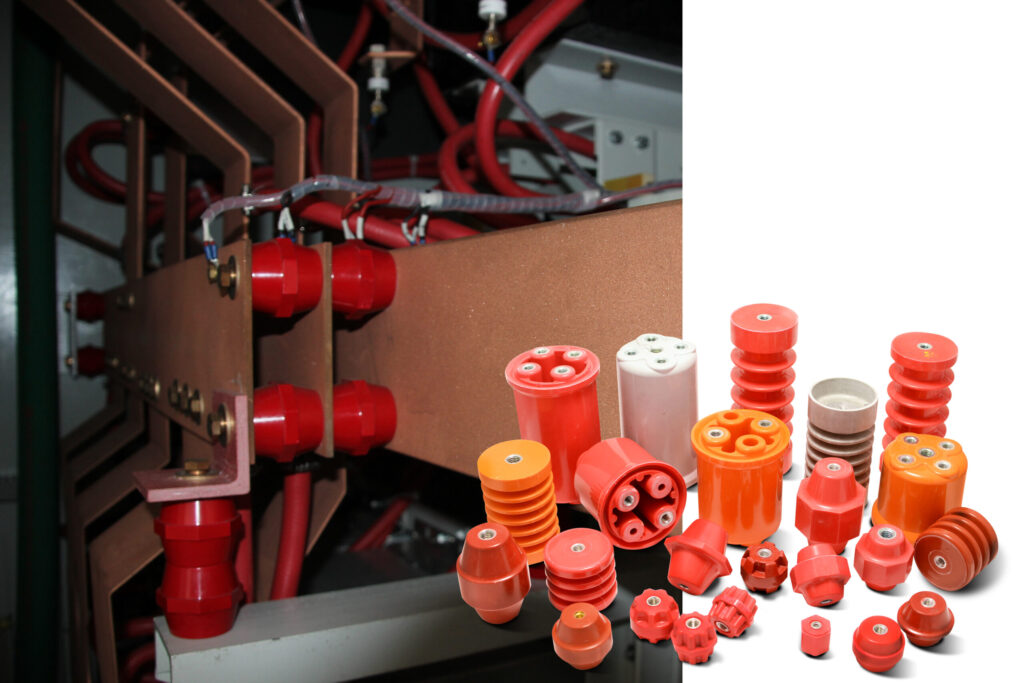

- Material Composition: Standoff Insulators are commonly made from materials like ceramic, plastic, or glass-reinforced epoxy.

- Design: Designed with specific shapes and dimensions to provide electrical isolation between conductive components.

Insulation Properties:

- Dielectric Strength: Insulators are engineered to withstand high voltages, providing effective electrical insulation between conductive components.

- Insulation Resistance: Offer high resistance to electrical current flow, ensuring proper electrical isolation.

Manufacturing and Applications:

Manufacturing Processes:

- Insulators are manufactured through processes such as molding, extrusion, or machining, ensuring precise dimensions and insulation properties.

- Varieties of shapes and sizes are available to suit different applications and mounting requirements.

Applications:

- Electrical Panels and Boards: Utilized in electrical panels to insulate and support bus bars, preventing electrical shorts.

- Electronic Circuits: Applied in PCBs to isolate and support components, ensuring electrical separation and stability.

- High-Voltage Applications: Used in high-voltage systems to provide insulation and maintain electrical safety.

Advantages and Considerations:

Advantages of Standoff Insulators:

- Electrical Isolation: Provide effective insulation between conductive components, preventing electrical shorts or faults.

- Mechanical Support: Serve as structural support elements, maintaining separation between components in various configurations.

Considerations:

- Voltage and Current Ratings: Selecting insulators with appropriate voltage and current ratings suitable for specific applications.

- Environmental Suitability: Ensuring insulators are resistant to environmental factors like moisture, chemicals, and temperature variations.

Standoff Insulators play a crucial role in maintaining electrical safety and integrity by providing effective electrical insulation and support in various electrical and electronic applications. Their insulation properties and structural support make them essential components in ensuring the reliability of electrical systems.